The Effect of High Dissolved Oxygen in an Aeration Tank

By: WebFx

Post Date: April 1st 2025

Dissolved oxygen (DO) plays a crucial role in wastewater treatment, and it’s critical to maintain proper DO levels in aeration tanks. Excess DO in aeration tanks can disrupt treatment efficiency and increase energy costs. Aerobic bacteria require oxygen to break down organic matter, but too much can lead to floc disintegration, excessive foaming and unnecessary aeration expenses. Wastewater engineers and plant operators must understand the effects of DO on protecting aeration tanks in water treatment processes.

Table Of Contents

- What Do Aeration Tanks Do in Wastewater Treatment?

- What Happens in the Aeration Tank?

- What Does High Dissolved Oxygen in Water Mean?

- What Is the Effect of High DO in an Aeration Tank?

- Monitoring and Controlling DO Levels

- Optimize Wastewater Treatment With SSI Aeration, Inc

What Do Aeration Tanks Do in Wastewater Treatment?

Aeration tanks are a central part of the wastewater treatment process. One treatment method is the activated sludge process, which uses microorganisms to turn water contaminants into sludge. This sludge settles together, leaving a layer of clear, clear water ready for disinfecting. The aeration tank adds oxygen to the water, encouraging microorganisms to grow and consume pollutants. The oxygen levels need precise monitoring to ensure the sludge process is balanced and efficient.

What Happens in the Aeration Tank?

Aeration tanks hold microorganisms that break down organic pollutants. Blowers or diffusers introduce air into the tank, encouraging microorganism growth. The microbes grow and consume the pollutants, and the DO levels are carefully maintained to ensure efficient, effective biological treatment.

In wastewater treatment, the DO is measured in milligrams per liter (mg/L). Ideally, DO concentrations in the tank stay within 2 to 4 mg/L during the process. This concentration keeps bacteria active without excessive aeration.

What Does High Dissolved Oxygen in Water Mean?

High DO levels in water mean the tank was over-aerated. Excess DO can also indicate a low oxygen demand. If the water is clean, with minimal pollutants, there’s less oxygen being removed from the water. Clean water needs replacement so the treatment process can continue.

The amount of oxygen that dissolves in the water is called “solubility.” The water’s temperature and other factors affect its solubility. The better the solubility and the more oxygen provided, the higher the amount of oxygen dissolved or mixed in the water is. It’s vital to maintain the right DO levels to ensure process efficiency and microbial activity.

What Is the Effect of High DO in an Aeration Tank?

High DO levels can significantly impact wastewater treatment. While maintaining an ideal range supports aerobic digestion, too much oxygen will disrupt sludge characteristics and interfere with an operation. These are the main effects excessive DO levels have on aeration system performance:

1. Wasteful Energy Use

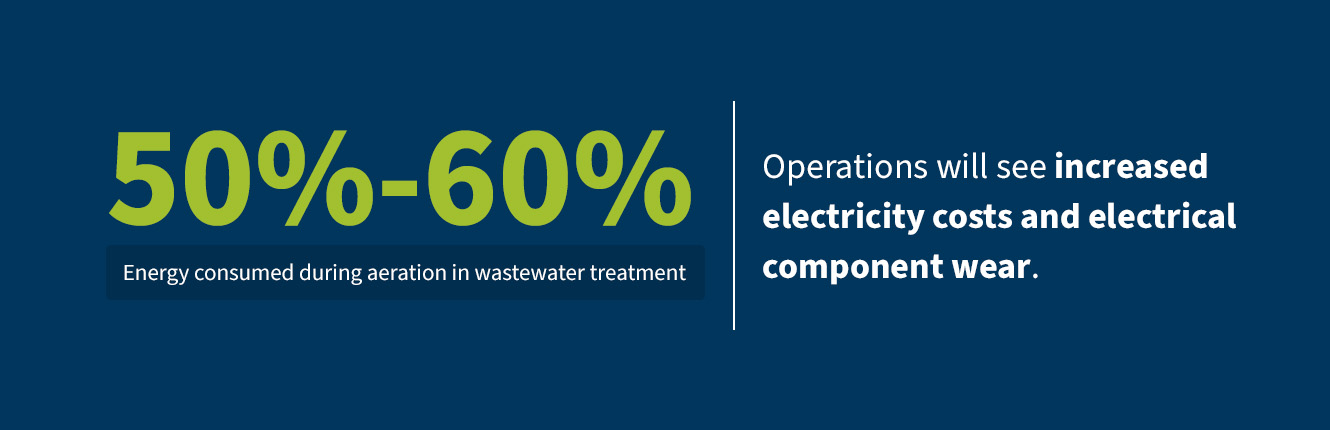

Aeration consumes a significant portion of wastewater treatment — around 50%-60% of all the energy used. When DO levels become too high, it’s likely due to over-aeration. Blowers and diffusers begin operation beyond what’s necessary for effective treatment, driving up this energy use beyond expected levels. Operations will see increased electricity costs and electrical component wear.

2. Floc Disruption

Proper sludge flocculation is critical for settling secondary treatment. When DO levels become too high, shear forces from prolonged aeration can break apart floc structures. This leads to poor settling and increased suspended solids. Operations should control DO levels to avoid reducing process efficiency and affecting water turbidity. Maintaining DO levels prevents floc disintegration, keeping solids seperated and sludge compacted. When floc is allowed to form, it’s easier to send clean water off for disinfection.

3. Filamentous Bacteria Growth

High DO can also create the right conditions for filamentous bacteria. These bacteria are a concern for treatment efficiency. When filamentous bacteria thrive, they disrupt sludge settling, leading to sludge bulking issues. Sludge fails to settle, extending the water treatment process. The less dense the sludge, the more difficult dewatering becomes and the more expensive handling is.

4. Impact on Nitrogen Removal

Excess DO can also increase nitrogen levels. Part of the activated sludge treatment process is denitrification — reducing nitrogen levels in the water. Bacteria reduce nitrate to nitrogen gas in aerobic conditions. Then, bacteria convert nitrate into nitrogen gas under anoxic conditions. However, excess DO in these anoxic zones can affect nitrate reduction. The bacteria latch onto the oxygen instead of the nitrate, reducing nitrogen removal efficiency.

Plants must properly control DO levels through careful monitoring and intermittent aeration or zone-based strategies to promote better nitrogen cycling.

Monitoring and Controlling DO Levels

Activated sludge systems depend on aerobic microorganisms to decompose organic matter. Plants must maintain and monitor DO levels to ensure optimal efficiency and cost control. Reduce energy consumption and improve treatment process quality through:

Regular Monitoring

Traditionally, plants monitor DO levels through manual sampling and laboratory analysis. These methods are time-consuming and lack real-time fluctuation data. Invest in sensors installed directly in the system to gather continuous, real-time data. Plants with more responsive monitoring can control aeration tank conditions faster, avoiding efficiency losses. Users can integrate these sensors into automated systems, adjusting aeration rates based on current DO levels.

Efficient Control Tools

Effective DO control involves regular aeration adjustment to match oxygen demand. Plants must ensure microorganisms receive the correct amount of oxygen to encourage the treatment process. Use these tools to create seamless DO level control:

- Automated aeration control: Integrate DO sensors with automated control systems. This solution allows facilities to easily adjust aeration rates, maintaining DO levels without manual intervention.

- Fine bubble diffusers: Fine bubble diffusers enhance oxygen transfer efficiency. These tools create more effective DO control while reducing energy consumption, for better efficiency and cost control.

- Variable frequency drives (VFDs): VFDs can be implemented on aeration blowers for precise airflow control. Plants can adjust the airflow in response to real-time DO measurements, improving DO management.

Risk Mitigation

When managing DO levels, operators and plant managers must consider other factors involved in the treatment process. Temperature, mixing and system design can all impact DO levels and treatment efficiency. Use sensors to monitor these factors and adjust DO levels as needed to avoid high DO content. The microbial community inside the aeration tank needs careful handling and precise care to ensure quality wastewater treatment. When oxygen requirements are not met, DO levels can rise quickly.

Additionally, regular maintenance of aeration equipment should be invested to protect operational efficiency. Calibrate sensors and maintain components to avoid wear and tear taking a toll on your DO level control. Better maintenance means more accurate sensor readings and improved control over aeration tank conditions.

Optimize Wastewater Treatment With SSI Aeration, Inc

Managing DO levels is critical for supporting effective water treatment systems. SSI Aeration provides high-quality aeration solutions to ensure these systems operate at peak efficiency. From fine bubble diffusers to custom design services, SSI Aeration can help plants meet their water treatment goals. These products are engineered to optimize oxygen transfer, minimize energy consumption and improve treatment performance.

Whether a wastewater plant requires a new aeration system or an existing setup upgrade, SSI Aeration has the expertise to assist. Reach out for a customized quote and a team member will be in touch.