How to Select the Right MBBR Media

By: Tom Frankel

Post Date: December 2nd 2020

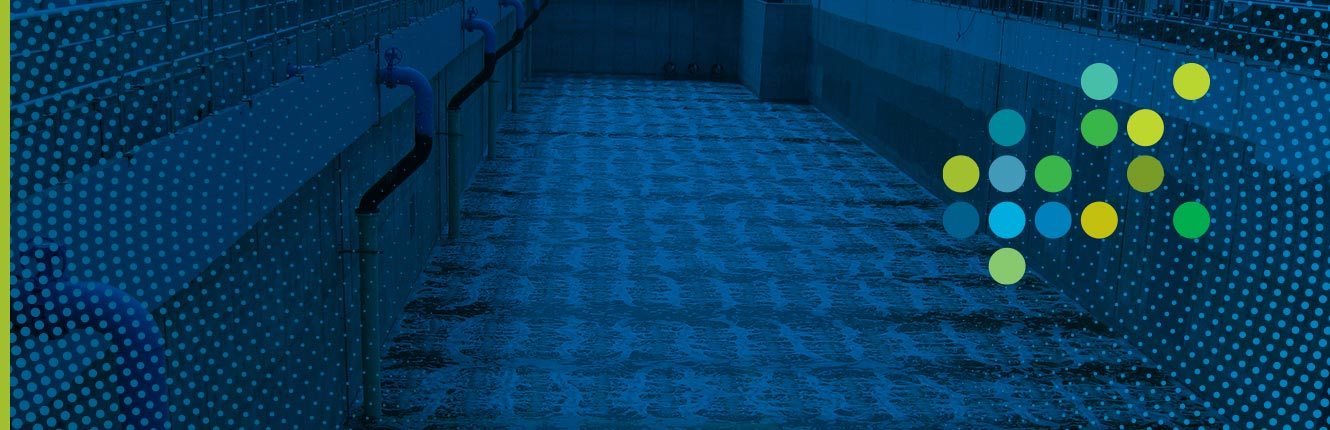

In secondary wastewater treatment, moving bed biofilm reactor (MBBR) media systems provide high-quality, low-cost and low-maintenance solutions. With various media types to choose from, though, knowing the right MBBR media specification for a given wastewater treatment tank can be a challenge. The guide below will explain what the MBBR process is, discuss MBBR floating media in detail and elaborate on how to choose between different MBBR media types.

Table Of Contents

- What Is the Purpose of MBBR Media?

- What Are the Benefits of MBBR Media

- What Are the Types of MBBR Media?

- MBBR Media Sizes

- MBBR Media Colors

- How to Select the Right MBBR Media

- MBBR Media Calculation

- What’s the Best MBBR Media?

- Benefits of SSI Media

- Performance Comparisons

- SSI Aeration Has the Best MBBR Media in the Industry

What Is the Purpose of MBBR Media?

What is MBBR technology in sewage treatment plants (STPs), and what purpose do MBBR media carriers serve?

A bed of MBBR media generally consists of thousands of tiny pieces that suspend themselves throughout a wastewater treatment tank, typically taking up about 50% to 70% of the available space. Their design makes them optimal for hosting beneficial bacteria and promoting their growth. Many types of MBBR media resemble wheel-shaped pasta, with the spokes of the wheel providing valuable surface area for bacterial growth. Others are thin, coin-shaped discs or squares.

MBBR media carriers are ideal for use in aeration tanks. They disperse throughout the tank, and their bacteria help decompose the solid waste. The media are so effective because their design gives them a tremendous amount of surface area for beneficial microorganisms to settle on, so they help increase the number of bacteria available to digest waste.

How Does MBBR Media Treat Wastewater?

How do the MBBR media carriers work? In an aeration tank, the tiny MBBR pieces disperse throughout the wastewater, and their tremendous surface area provides a hospitable environment for microorganism growth. The biofilm that grows on the media then decomposes the waste in the tank.

Diffusers send oxygen into the tank to promote continuous microorganism growth, and a mesh sieve in the tank helps keep the media carriers from flowing away with the wastewater. MBBR media carriers have a density similar to that of water, so they mix well with the wastewater to promote consistent waste digestion.

Using MBBR media is particularly advantageous because the tiny pieces take up minimal space, are easy to maintain and digest waste efficiently. The microorganisms on the media can eat.

What Are the Benefits of MBBR Media

Wastewater treatment facilities experience numerous benefits from implementing MBBR media technology. These advantages position MBBR media as a strong alternative to traditional processes like activated sludge and membrane bioreactors:

- Space efficiency: A small amount of MBBR can treat the same volume that processes like activated sludge and trickling filters need massive tanks to treat. Your facility will have more space for other valuable machinery.

- Ease of use: Biofilm reactors are easy to operate, even for inexperienced staff. The system naturally adjusts to changes in surface area loading rate (SALR), wastewater flow rate, biological oxygen demand (BOD) and nitrate or ammonia concentration. Operators calculate the MBBR system’s design, then allow it to work its natural processes.

- Infrequent maintenance: MBBR systems operate independently with minimal maintenance needs. Aeration grids facilitate constant motion in the tank, preventing media clogs. The system also naturally sets its productive biofilm levels to an optimal rate.

- Load flexibility: Fixed film and suspended growth biological processes enable MBBR systems to resist disruption. This flexibility provides stability when handling shock loads or sudden fluctuations in chemical composition.

- Rapid hydraulic retention: After switching from other media, facilities will treat more water each day thanks to a low hydraulic retention time (HRT). MBBR treats liquids faster due to the media’s constant motion, improving your water treatment capabilities.

What Are the Types of MBBR Media?

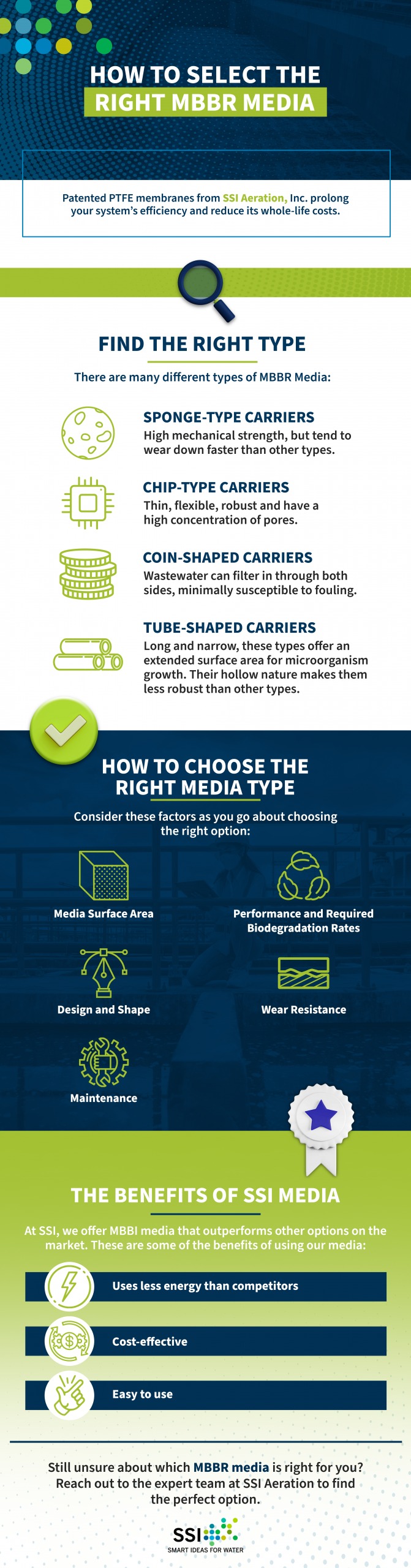

Below are a few of the different MBBR media types:

- Sponge-type carriers: Sponge-type MBBR media carriers have high mechanical strength, a high specific surface area, and a rough surface texture optimal for biofilms to take hold on. Their spongy materials are incredibly flexible, though they tend to wear down more easily than other types.

- Chip-type carriers: Chip-type carriers are thin and have a high concentration of fine pores. They are flexible as well, and they offer robust resistance to wear and tear.

- Coin-shaped carriers: Thin, coin-shaped media carriers provide the advantage that wastewater can filter into them from either side of the media, so they are minimally susceptible to fouling. Some thin chip-type media carriers are coin-shaped.

- Tube-shaped carriers: Long, narrow tube-shaped carriers offer an extended MBBR media surface area for microorganism growth. Their shape also helps them suspend evenly within the water column instead of stacking on top of one another. Because of their hollow forms, though, they can sometimes become susceptible to fouling.

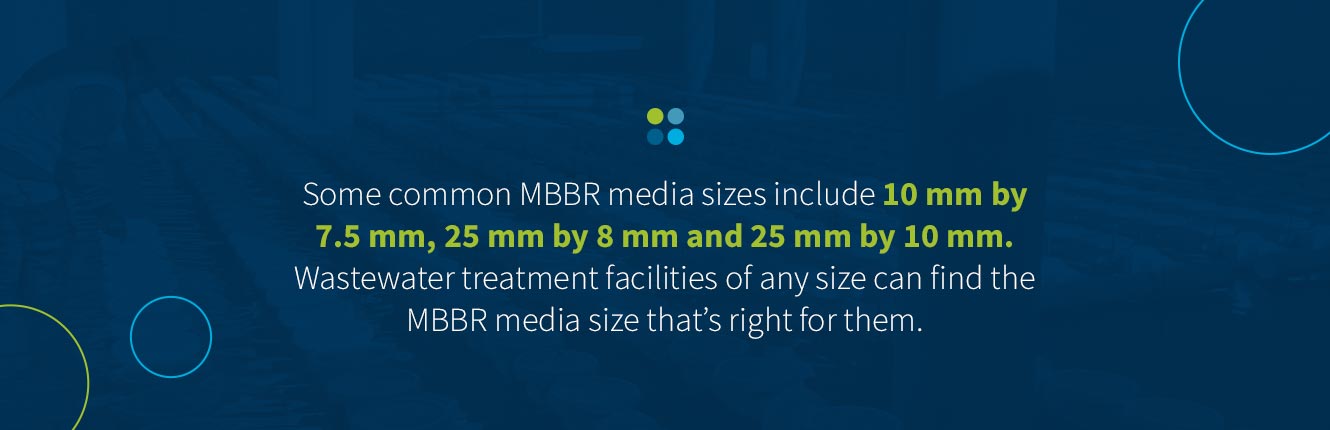

MBBR Media Sizes

MBBR media sizes can vary, and many manufacturers are willing to create custom sizes to meet the needs of any wastewater treatment facility. Some common MBBR media sizes include 10 mm by 7.5 mm, 25 mm by 8 mm and 25 mm by 10 mm. Wastewater treatment facilities of any size can find the MBBR media size that’s right for them.

Part of knowing how to select MBBR media is understanding the size you need. Call your MBBR media manufacturer and supplier to see what sizes are available so you can choose the best one for your situation.

MBBR Media Colors

You have some customization options regarding the color of your wastewater treatment facility’s MBBR media. The most common available color is white, but you can also find MBBR media in red, green, blue and brown. Choose the right color to fit your facility’s appearance while following any required standards.

How to Select the Right MBBR Media

To select the correct moving bio bed media for your wastewater applications, you’ll want to consider a few different factors.

Media Surface Area

Adequate surface area is necessary to facilitate microorganism growth. Media surface area sometimes correlates with biodegradation rates, but other factors can affect biodegradation as well, so the correlation is not a perfect one.

In general, a wastewater treatment plant should maximize media surface area while still making sure the media carriers meet the facility’s needs in their other characteristics. MBBR media carriers in the shape of spoked wheels, for example, offer a tremendous surface area for their size to help a plant meet its waste digestion needs.

Performance and Required Biodegradation Rates

Optimal performance and biodegradation rates are critical for helping a plant move wastewater through secondary treatment quickly and efficiently. Performance and biodegradation rates often rise with increased media surface area. They also depend on factors like influent and effluent characteristics, fluctuations in the wastewater’s pollutant concentrations, the tank’s minimum temperature, and the biological metabolisms of the tank’s microorganisms.

In general, to optimize performance and biodegradation rates, plants should seek out MBBR media carriers of the correct shape and material quality to provide efficient, effective waste digestion.

Design and Shape

As we’ve discussed above, the design and shape of MBBR bio-media carriers help determine waste breakdown efficiency and effectiveness. Media carriers with intricate, cut-out shapes tend to offer more surface area per media weight to enhance bacterial growth and promote biosolid breakdown.

The MBBR media carriers’ design should also give them a density close to the wastewater’s density. The right density promotes even dispersal throughout the tank and ensures thorough waste digestion. Different materials offer different densities — the more economical re-granulates, for instance, may have substantial fluctuations in density between carrier pieces, whereas polyethylene may provide more consistency.

Wear Resistance

The wear-resistant characteristics of MBBR media carriers determine how they hold up to the demands of wastewater treatment. More resistant media carriers last longer and require fewer changes over time. Some MBBR media carriers, such as sponge-types, have limited resistance to abrasion, so they wear out more easily. Chip-type carriers tend to offer better resistance and a longer life span. Tube-shaped versions may suffer wear because the insides of the tubes tend to accumulate biomatter, which then dies and inhibits active waste digestion.

Maintenance

MBBR media systems require relatively little maintenance. Some materials like polyethylene last longer than others and minimize maintenance needs, so facility managers will want to look into different materials and determine what life span the plant requires for its media.

MBBR Media Calculation

How is MBBR media volume calculated? To calculate the number of media carriers a facility may need for a wastewater tank, it should first determine the organic load of its wastewater. The organic load will be more or less equal to the product of the flow rate and the difference between the influent and effluent concentration.

- Organic load = flow rate x (influent concentration – effluent concentration)

Once a facility has determined its flow rate, it can then calculate the necessary media supply. Generally, the carrier amount is equal to the wastewater’s organic load divided by the media’s removal efficiency.

- Carrier amount = organic load / removal efficiency

An engineer or facility manager will need to check on the removal efficiencies of the different media under consideration and plug those values into the equation to determine the necessary media carrier volume.

What’s the Best MBBR Media?

SSI Aeration’s MBBR is the best bio-filter media available. The resin we use to produce our MBBR media gives it the ideal density of just under the specific gravity of water, which leads to better energy efficiency for your wastewater treatment facility. When you need to mix the water, very little air is required to get the MBBR media moving.

Our competitors use media with lower specific gravity. This forces wastewater treatment facilities to use more energy, as more air is required to get the MBBR media to submerge and mix throughout the tank. Consider how much energy is needed to use air to push floating MBBR media to the deeper sections of a holding tank. The more air you need for this process, the more money you’ll spend on energy.

With SSI Aeration’s MBBR media, you can use less air when mixing your holding tanks because of the greater density of the media itself. The media needs less air to push it deeper and through the tank, ensuring the most efficient process possible.

Benefits of SSI Media

As you search for the right MBBR media solution for your needs, consider these benefits of MBBR media from SSI Aeration:

- Cost savings for wastewater treatment facilities: Since you’ll be using less energy thanks to the greater density of SSI Aeration’s MBBR media, your wastewater treatment facility will save money on your utility bills. This can help you gain higher profits and ensure you reach your facility’s monetary goals every period.

- Cost savings for end users: End users rarely think about the media their wastewater treatment facilities use when processing their wastewater. They simply trust the treatment provider to treat their water at an affordable rate. When you save money on energy thanks to SSI Aeration’s MBBR media, you can also pass those savings on to your end users.

- Easier operations: SSI Aeration’s MBBR media systems efficiently use the power of microorganisms to break down solid waste in the water. This means controllers have fewer duties to manage for easier operating procedures.

- Less operator intervention: Easier operating procedures mean there will be less need for operator intervention.

- Space savings: SSI Aeration’s MBBR systems have a low hydraulic retention time, which allows for the use of smaller reactors to save space in your wastewater treatment facility.

Performance Comparisons

In an industry filled with different types of MBBR media, SSI’s media carriers stand out. SSI’s MBBR systems offer numerous advantages over competitors’, including custom in-house diffuser and media creation, outstanding media and diffuser interactions, and clean systems that will remain free from flies, slugs and other pests. SSI Aeration’s EEvolved MBBR systems also incorporate a patented technology and innovative biofilm that provide superior effectiveness, efficiency and safety.

Why Choose SSI for MBBR Media?

The design experts at SSI Aeration have advanced the MBBR process. Leveraging innovation and industry expertise allows us to offer unique advantages over the competition and improve daily operations. We offer a wealth of capabilities and qualifications that position our organization and MBBR process as the best choice for wastewater treatment facilities, such as:

- In-house media and diffuser creation: Our engineers will fabricate MBBR media and diffusers according to your facility’s specifications and applications.

- Optimal media and diffuser interactions: We design media for the diffuser, leading to efficient interaction that streamlines the MBBR process.

- Experience across industries: Our experts have years of experience designing solutions for multiple industries. We’ll leverage our expertise to develop a practical MBBR solution for your plant.

- Commitment to learning your needs: Our research and development team optimizes the MBBR process for your industry and facility by uncovering new insights that allow us to innovate and boost operational efficiency.

- Energy-efficient methods: Our efficient MBBR media requires less energy to mix than competing MBBR options, and the overall energy reduction will keep your facility’s operational costs low.

SSI Aeration Has the Best MBBR Media in the Industry

To see the benefits of a quality MBBR system in your wastewater treatment facility, make SSI Aeration your trusted source. SSI systems’ advanced hydrodynamics, aeration, media construction, and biofilm make wastewater processes more efficient, reduce maintenance, and help a facility meet its unique wastewater treatment goals.

Request an MBBR quote today.

Mr. Frankel co-founded SSI in 1995 with experience in design and distribution of engineered systems. He is in charge of sales, marketing and operations in the company. Mr. Frankel holds multiple US patents related to diffusers. He is a graduate of Washington University in St. Louis.