Contact Us Today

Moving Bed Biofilm Reactor (MBBR) Wastewater Treatment Systems

Moving bed biofilm reactor (MBBR) systems offer a revolutionary approach to biological wastewater treatment. With SSI Aeration Inc.’s MBBR systems, facilities can save on costs, energy and space while enhancing their overall operations.

Why MBBR?

SSI Aeration’s comprehensive design and engineering processes contribute to the unique advantages the MBBR systems provide. The MBBR engineers at SSI focus on minimizing the following elements:

- Energy and operating cost: MBBR systems have optimal energy efficiency, resulting in lower operational costs.

- Reactor volume and HRT: SSI Aeration’s MBBR systems have low hydraulic retention time (HRT), which enables MBBR to operate effectively in smaller reactors.

- Control complexity: Since MBBR systems use a biological treatment process, microorganisms are responsible for the majority of the treatment. As a result, the system requires less operator attention and intervention, making operation simple.

- Footprint: An MBBR system uses biofilm carriers, which provide substantial surface area for microbial growth. The additional mass of microorganisms offers more treatment capacity in a relatively smaller footprint.

Additionally, SSI MBBRs increase factors such as:

- Treatment efficiency: An MBBR offers better treatment efficiency than other types of wastewater treatment systems at lower space and budget requirements.

- Hydraulic capacity: MBBR systems can handle more water at a given time than other systems, enhancing overall efficiency.

- Volumetric efficiency: With bacteria managing much of the treatment process, the parts in an MBBR system can stay in better condition. As a result, the system optimizes the amount of water flowing through the pumps.

- Process life span: The biofilm media carriers that hold an MBBR system’s bacteria have a long life expectancy. In turn, the system’s process lifespan also increases.

SSI’s MBBR systems increase performance and cost-effectiveness through smart design principles.

Service Advantages

When wastewater treatment facilities work with SSI on MBBR wastewater systems, they gain the following benefits:

- In-house media creation: SSI engineers and fabricates its own media to exacting specifications and superior quality.

- In-house diffuser creation: SSI also engineers and fabricates its own diffusers to ensure maximum quality and performance.

- Superior media and diffuser interface: SSI specifically designs its media to work with its diffusers. Working with SSI helps ensure complete compatibility between diffusers and media for the most streamlined operations.

- Industry-specific experience: SSI has dozens of years of experience designing and building MBBRs for a multitude of industries, including the food, textile, and petroleum-processing industries, as well as the pulp-and-paper manufacturing and chemicals manufacturing industries.

- Multidisciplinary expertise: SSI is one of the only companies where clients will find expertise in diffuser manufacturing, media manufacturing, and MBBR design all under the same roof. This unmatched array of knowledge allows SSI teams to work together with multidisciplinary approaches to give clients the best experience possible.

- Practical, experience-based solutions: The practical benefits of SSI’s multidisciplinary expertise are numerous. SSI has studied which resins to use to produce media, so they mix with the least expenditure of energy. SSI has determined which diffuser size and coatings work best to minimize maintenance. Plus, SSI knows what problems plants could encounter with their MBBRs — such as overflows from failed retention screens — and can take precautions to prevent these issues before they occur.

- Robust R&D program: SSI has a strong research and design program that is active in pursuing new methods and designs for media production and MBBR system installation. The R&D team is also engaged in analyzing and engineering for the interactions between media and diffusers in MBBR systems.

- Library of SOTE resources: SSI also has an immense library of resources for standard oxygen transfer (SOTE) testing. We can apply these resources to help optimize MBBR system design and performance in terms of oxygen transfer.

- Extensive IFAS experience: SSI has extensive experience with integrated fixed-film activated sludge (IFAS), which requires less volume than conventional activated sludge systems, requires less maintenance and involves fewer capital costs. We can supply these systems with fixed media and have expertise in operating them.

- Superior, clean IFAS systems: SSI’s IFAS systems are some of the best — and best-maintained — in the industry because we can keep them free from undesirable organisms like flies, leeches and slugs. Being proactive in this way helps keep MBBR systems running efficiently.

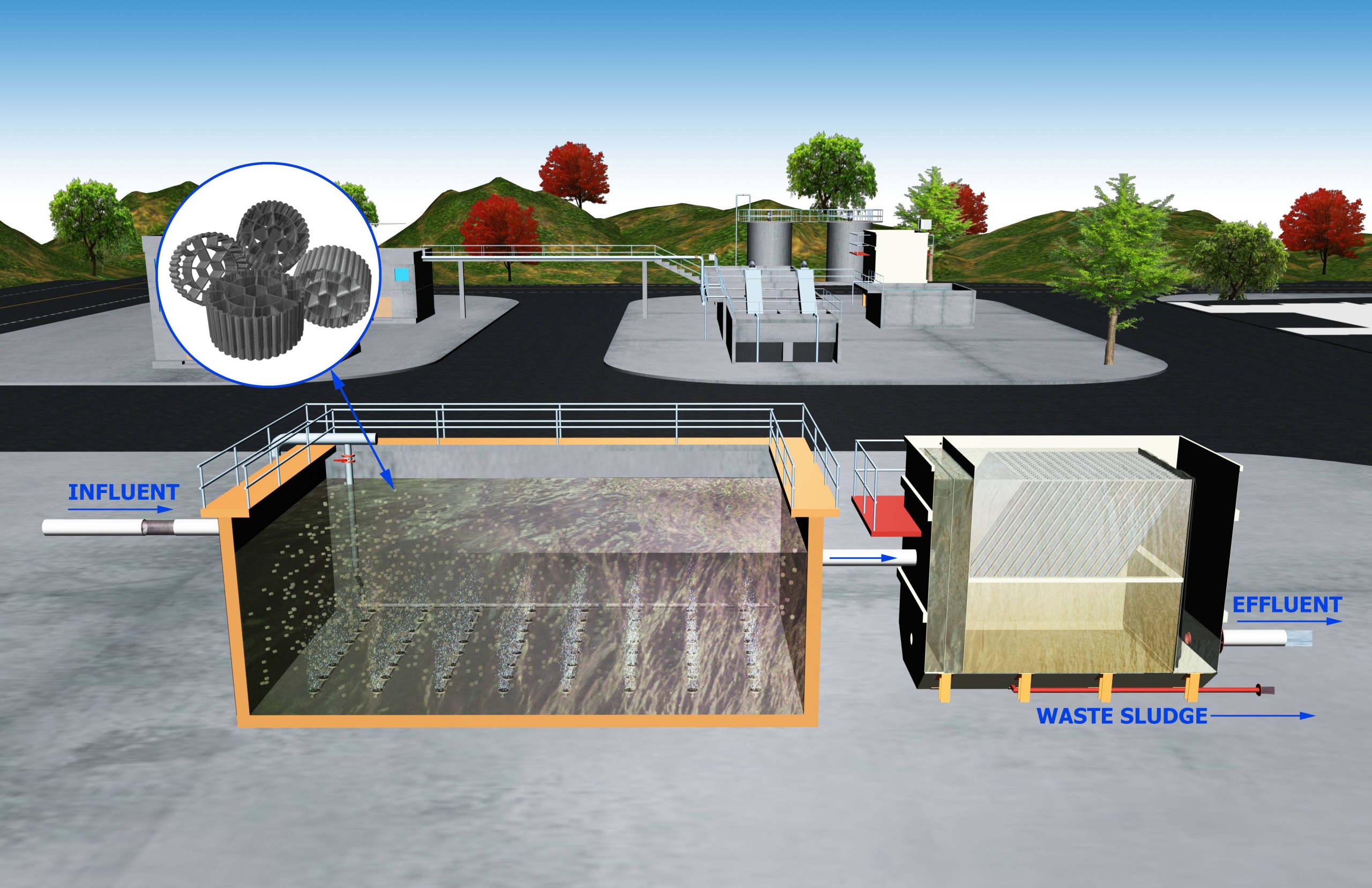

EEVolved MBBR for Biological Treatment

The energy-efficient volumetrically optimized low volatile effluent discharge moving bed biofilm reactor system, or EEvolved MBBR, is an SSI Aeration innovation engineered to provide high-rate biological treatment. The design combines SSI’s outstanding MBBR technology with its superior diffuser and media performance.

SSI Aeration’s media is produced in-house with high-quality materials to ensure proper buoyance, strength and longevity. The team also uses media with geometry that suits the specific system to promote adequate biological growth. SSI Aeration’s EEvolved MBBR system is designed to help clients achieve greater efficiency, reduce aeration maintenance and facilitate safer system operation.

Low Hydraulic Retention Time

The amount of time soluble compounds or wastewater remains in an aeration tank significantly impacts the overall efficiency of wastewater treatment in a plant. SSI Aeration Inc.’s MBBR systems have a low hydraulic retention time, meaning wastewater spends a relatively short time in a reactor on average before moving to the next stage of treatment.

SSI Aeration has engineered these systems to provide increased volumetric efficiency in reactors with smaller sizes. As a result, the systems can optimize hydraulic retention time without compromising the effectiveness of the processes.

Partner With SSI Aeration for Your MBBR Needs

SSI Aeration’s moving bed biofilm reactor technology and systems are the ideal choice for various applications where compact, durable and low-cost wastewater treatment solutions are required. Contact us online to connect with the experts from SSI Aeration or to learn more about our systems.

Contact Us

Advantages and Disadvantages of MBBR Wastewater Treatment

Table Of Contents WHAT IS MBBR WASTEWATER TREATMENT? HOW DOES MBBR WASTEWATER TREATMENT WORK? ADVANTAGES OF MBBR WASTEWATER TREATMENT DISADVANTAGES OF MBBR WASTEWATER TREATMENT INDUSTRIES THAT WOULD BENEFIT […]

EPDM vs. PTFE Membranes

Table Of Contents What Are EPDM Membranes? What Are PTFE Membranes? Choosing the Right Membranes for Your Application Contact SSI Aeration for World-Class EPDM and PTFE Membranes Many wastewater […]

A Comparison Of 5 Wastewater Aeration Systems & Processes

Table Of Contents WHAT IS ASP AERATION? HOW DOES ASP WORK? PROS AND CONS OF ASP WHAT IS SBR AERATION? HOW DOES SBR WORK? PROS AND CONS OF […]

Disc Diffusers vs. Tube Diffusers

Table Of Contents WHAT IS THE DIFFERENCE BETWEEN DISC DIFFUSERS AND TUBE DIFFUSERS? Pros of Disc Diffusers Cons of Disc Diffusers Pros of Tube Diffusers Cons of Tube Diffusers […]