Contact Us Today

EPDM Membranes for Aeration Diffusers

SSI FIELD TESTS EPDM DISC MEMBRANES AND TUBE MEMBRANES FOR LIFESPAN AND DEPENDABILITY

SSI’s (EPDM) rubber membranes demonstrate outstanding results in field testing, both with fine bubble disc diffusers and fine bubble tube diffusers. We manufacture all EPDM diffuser membranes in our factory using new injection molding machines. We also perforate our own parts in-house.

Features and Benefits of SSI’s EPDM Membranes

Diffuser membranes from SSI Aeration, Inc., have worldwide recognition for their quality and performance. Consider the features and benefits of these EPDM membranes below.

Low Plasticizer Content

Low plasticizer content means the membrane will last longer before it hardens, shrinks or breaks. Outsourced vendors often use more plasticizers to make their rubber materials softer and more flexible. However, when EPDM rubber has too many plasticizers, they can migrate out in tiny droplets over time, resulting in membrane weight loss and failure. For this reason, SSI Aeration designs and engineers EPDM membranes for aeration diffusers with a low concentration of plasticizers to promote long-lasting performance.

Disc Diffuser Membranes

Disc diffuser membranes from SSI Aeration, Inc. can fit SSI fine bubble disc diffuser bodies and models from other manufacturers. SSI develops membranes for 7-inch, 9-inch, 12-inch and 20-inch disc diffusers. The SSI team has a worldwide reputation for high-quality engineering that focuses on reliability and performance. We can find a custom solution for any client's wastewater aeration system.

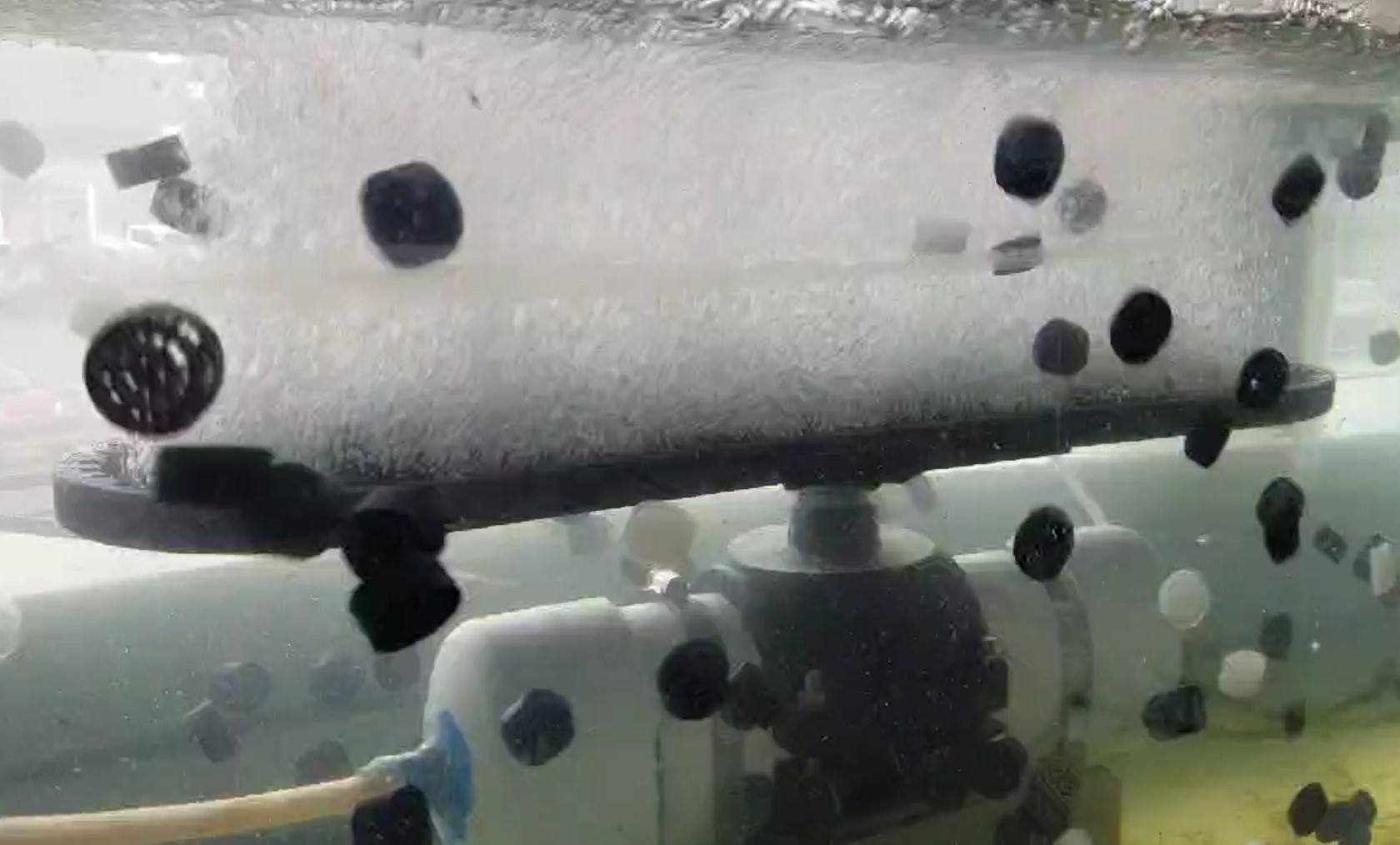

Tube Diffuser Membranes

SSI Aeration, Inc. can also manufacture membranes for 62mm and 91mm tube diffusers. We use similar materials and methods to create tube diffuser membranes as we do for disc diffuser membranes. As a result, clients can expect a comparable level of performance. Plants that use a variety of diffuser models can depend on SSI's quality membrane design for competitive results.

Plate Diffuser Membranes

SSI Aeration, Inc. manufactures several plate diffuser membranes, including the patented PTFE membrane. These membranes are designed to fit SSI's ECD650 plate diffuser systems. The membranes feature precise engineering to prolong the system's efficiency and reduce overall maintenance costs.

High Tensile Strength and Elongation at Break

EPDM diffuser membranes with high tear resistance have tensile strength and elongation at break that exceeds industry standards. Nobody expects a membrane to stretch to 700% of its resting length. However, tensile strength and elongation are still essential for performance and longevity. With higher elongation at break, the EPDM diffuser membrane has better snapping back capabilities for closing the slits and less chance of creeping or permanently deforming over time.

Heat and Light Resistance

EPDM diffuser membrane material from SSI Aeration, Inc. has a saturated polymer backbone, making it resistant to heat, steam and brightness. As a result, the membrane can withstand harsh weather conditions and high temperatures.

PFAS-Free

SSI Aeration’s EPDM diffuser membranes and coatings do not contain Per- or poly-fluorinated alkyl substances (PFAS), otherwise known as ‘forever chemicals’. These substances are widely used in an array of products, including rubber manufacturing. However, they may have harmful and persistent effects on the environment, human health and animal life.

We manufacture PFAS-free products in an effort to reduce their environmental impact and prevent them from causing further harm.

Replacement and Retrofitting

SSI’s premium membranes are available as direct replacements for SSI and as an upgrade for most other brands. We can also provide diffuser installation services. The SSI team can partner with clients to develop solutions for retrofitting projects.

Besides EPDM, SSI also produces PEEK, EPDM, Silicone, and Polyurethane membranes.

The sales and engineering teams can help customers find the right material for their applications. SSI offers membranes with a variety of sizes, shapes and price points to suit multiple situations. Customers can retrofit SSI membranes on diffuser bodies from three different manufacturers. This versatility gives clients more control over their aeration system modifications.

Scheduled Obsolescence

We use scheduled obsolescence to determine the end of life of our membrane tooling. When you have just a few molds and fixtures, you may be able to follow a different protocol. SSI Aeration takes a different approach to quality control to accommodate our widespread offerings. We count the cycles on our molds and perforation knives and change them on a schedule. This is because an old mold makes parts with uneven thickness, and old knives make rough slits that may not bubble uniformly across the part.

Advanced Coatings and Compounds

Advanced Coatings and Compounds

Customers may choose from standard EPDM membranes or EPDM membranes with special coatings or manufacturing techniques. Consider the following options for extending an EPDM membrane’s performance:

- PTFE: SSI’s patented PTFE membranes consist of an EPDM substrate with a PTFE coating. The PTFE layer protects the EPDM base from chemicals and resists surface fouling for improved performance. Based on preliminary results, SSI expects PTFE to have even lower life cycle costs than EPDM.

- Silicone: An inorganic material with high temperature resistance. SSI’s silicone membranes are specially formulated for high tear strength.

- Polyurethane: A very strong material which may be suitable for some industrial wastewaters when operating continuously.

Cutting-edge materials make membranes from SSI Aeration, Inc. the worldwide choice across industries.

EXCELLENT OXYGEN TRANSFER EFFICIENCY AND LONGEVITY

SSI Aeration, Inc. has provided excellent oxygen transfer efficiency and longevity in many municipal and industrial applications for over 20 years. Few companies have remained in the founders’ hands for so long. SSI has had the good fortune to keep our turnover very low, resulting in very knowledgeable people at all levels of the company. Since SSI has so many seasoned experts on staff, we can always improve upon previous results.

Reliable Performance

SSI membranes are built to provide stable performance with minimal shrinkage, cracking/crazing or creep/stretching over time. We use a low plasticizer content to improve flexibility and durability. During manufacturing, we add just enough plasticizers to maintain the right structure for aeration performance. Our compression molding techniques create a uniform surface area that resists tearing.

Head Loss Mitigation

Often the difference between two brands is the head loss. SSI has designed our diffuser cross-sectional thickness, uniformity and perforation knives to provide the lowest possible dynamic wet pressure (DWP) across membranes. Please visit SSI CurveGen(TM) for more data on a specific product.

Cost Efficiency

We have innovated lower-cost ways to deliver oxygen to your process through innovation. The single molded diffuser was developed at SSI, which uses the same high-quality membrane as our conventional products, but in an economical package. Have a look at our EC series tube and disc diffusers.

Discover More About EPDM Diffuser Membranes for Sale

Count on SSI Aeration, Inc. as the worldwide EPDM diffuser membrane manufacturer. To learn more about the worldwide choice for Custom-Molded EPDM Membranes, fill out the form below and one of our experts will contact you. Prospective customers may also request a quote online or contact a sales representative to learn more about pricing and selection.

Contact Us

Advantages and Disadvantages of MBBR Wastewater Treatment

Table Of Contents WHAT IS MBBR WASTEWATER TREATMENT? HOW DOES MBBR WASTEWATER TREATMENT WORK? ADVANTAGES OF MBBR WASTEWATER TREATMENT DISADVANTAGES OF MBBR WASTEWATER TREATMENT INDUSTRIES THAT WOULD BENEFIT […]

EPDM vs. PTFE Membranes

Table Of Contents What Are EPDM Membranes? What Are PTFE Membranes? Choosing the Right Membranes for Your Application Contact SSI Aeration for World-Class EPDM and PTFE Membranes Many wastewater […]

A Comparison Of 5 Wastewater Aeration Systems & Processes

Table Of Contents WHAT IS ASP AERATION? HOW DOES ASP WORK? PROS AND CONS OF ASP WHAT IS SBR AERATION? HOW DOES SBR WORK? PROS AND CONS OF […]

Disc Diffusers vs. Tube Diffusers

Table Of Contents WHAT IS THE DIFFERENCE BETWEEN DISC DIFFUSERS AND TUBE DIFFUSERS? Pros of Disc Diffusers Cons of Disc Diffusers Pros of Tube Diffusers Cons of Tube Diffusers […]