Contact Us Today

Fine Bubble Tube Diffusers

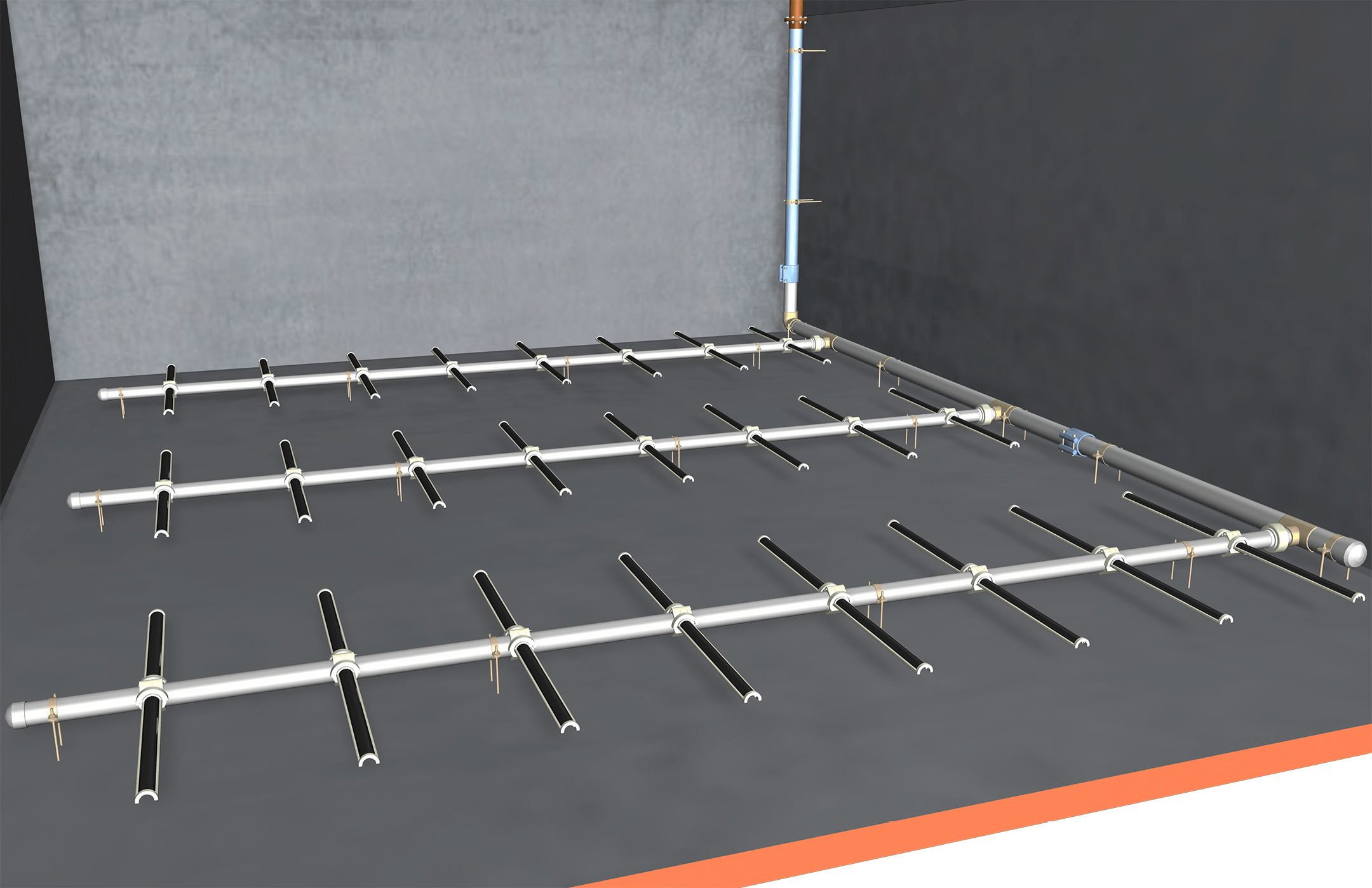

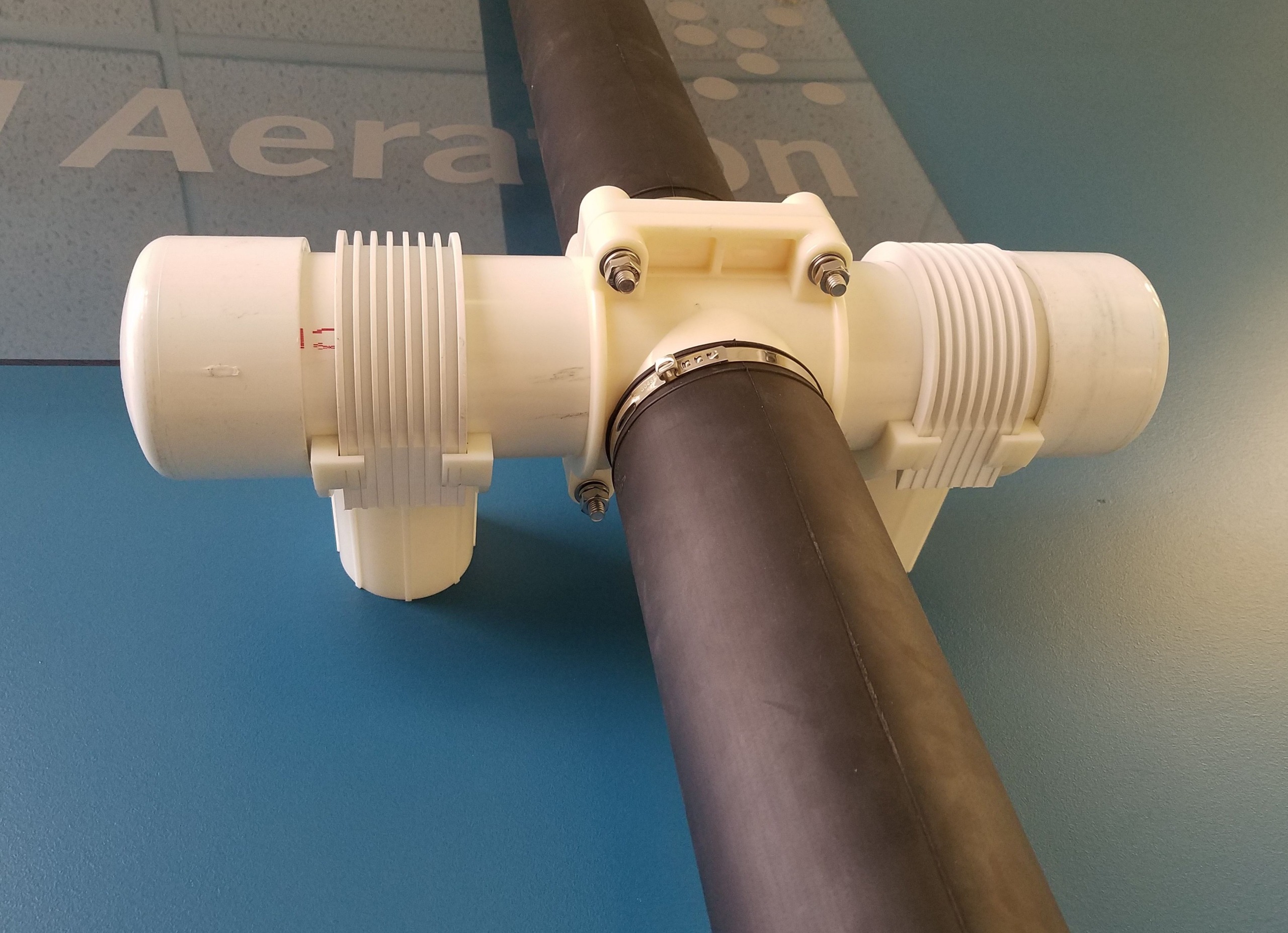

Thanks to its advanced membrane materials, SSI Aeration’s fine bubble tube diffuser has outstanding chemical and fouling resistance. This advanced design also provides high oxygen transfer efficiency (SOTE). Our product is different from other brands, because of our patented channel-pipe support. SSI Channel Pipe looks like this:

Most tube diffusers are built on round pipe. When the membrane is inflated, the inside of the membrane sticks to the pipe. SSI’s channel pipe provides small air pathways all the way to the end of the diffuser. This creates a uniform bubble pattern across the whole length of the diffuser.

Another advantage of the channel pipe is that it is resistant to folding (flexure) tears along the perforation lines. The membrane fits snugly over the channeled support pipe, so it is nearly impossible to crease.

All of SSI’s tube diffusers also have a step built into the support pipe plastic body, which prevents the membrane from sliding over time.

The SSI Advantage

- Industry standard size and shape, interchangeable with other systems

- Connector options: standard nipple pipe connection or SSI’s Snappy Saddle™ Mount which makes one-person installation easy

- Variety of lengths, diameters, and membranes in 21st-century materials

- Excellent fouling resistance and longevity thanks to high quality EPDM, PTFE-coated surface layers, silicone and polyurethane options.

- Multiple integral check valves to keep your aeration piping system clean

- Molded membranes with individual thermocouples in each cavity provide 100% quality control

- Low membrane plasticizer content to reduce shrinkage and hardening, but enough to avoid creep

- 212F (100C) temperature resistance and environmentally friendly high-temperature ABS body

- Fittings are available for mounting to metric or US pipe, and for tight spaces or for ease of installation

- Personal design assistance is available, as well as free software on our Technology Portal.

- Affordably priced for first use or retrofit

As the worldwide choice of fine bubble tube diffuser manufacturers, SSI Aeration, Inc. offers dependable products. Learn more about the selection below.

Universal Design

Each fine bubble tube diffuser for sale has an industry-standard size and shape. They have designs that make them interchangeable with other systems to provide added flexibility. SSI’s tube diffusers find use in brand new installations, repairs and modifications because of their versatile engineering. Fittings are available for mounting to metric or US pipe, and for tight spaces or for ease of installation. The SSI team can create aeration fine bubble tube diffuser specifications that suit the client’s project wherever they work.

Multiple Connector Options

SSI fine bubble tube diffusers can have one of the following connector types:

- Standard connection: Tube diffusers can come with a standard nipple pipe connection for compatibility with existing systems or other parts.

- Bolted Saddle connection: You can mount SSI tube diffusers with bolt-on saddles onto 3″ and 4″ pipe. This method is often used to retrofit other brands.

- SSI’s Snappy Saddle™ mount: The Snappy Saddle™ connection makes one-person installation easy for new systems with small labor teams. A special feature of this product is the single orifice on top of the pipe, which is superior to orifices on the two sides of pipe.

These options allow clients to find a connector that fits their project’s needs.

Wide Selection of Sizes and Materials

SSI produces fine bubble tube diffusers with various membrane types, diameters and lengths. Tube membrane materials include:

- PTFE coated EPDM

- EPDM

- Silicone

- Polyurethane

When SSI develops membranes, the manufacturers focus on materials with stellar chemical and fouling resistance.

Cleanliness and Reliability

Tube diffusers from SSI have the same level of efficiency and reliability built-in as the rest of the company’s product lines. Every diffuser has several integral check valves that help aeration piping stay clean. They also have a high-temperature resistance of 212°F (100°C) thanks to a high-temperature ABS body. SSI designs all products, including fine bubble tube diffusers, with performance and durability in mind.

Precise Membrane Manufacturing

Fine bubble tube diffusers feature SSI’s signature membranes, which experts develop with precision. Manufacturers use compression molding to form the membranes, which also have individual thermocouples for each cavity. These details ensure a high level of quality control and uniformity among products. The molding process also involves a low plasticizer content to reduce shrinkage and hardening. Each membrane has just enough plasticizer to avoid creep.

Snappy Saddle™ Diffusers

An SSI fine bubble tube diffuser equipped with the Snappy Saddle™ mount simplifies the installation process for a client's system project. The single seal on top of the header serves as a fast yet reliable alternative to dual seals. A singular seal prevents damage over time and shortens installation. SSI engineered the Snappy Saddle™ diffusers for set up by one person, reducing labor requirements.

Tube Diffuser Replacement Parts

If you are operating with old diffusers, you are probably losing a lot of money on wasted power. SSI manufactures replacement parts for many different brands and sizes of tube diffusers, including tube membranes. These include EPDM, PTFE, silicone, and polyurethane. We can replace membranes and clamps, and sometimes even the entire diffuser, without changing the piping system. We offer long stainless nipples for square pipe, and saddle or grommet mounts for the round pipe.

ECT Tube Diffusers

If you are in the market for tube diffusers, you may also want to check out SSI's ECT series. The ECT product belongs to our family of single-molded products, which means that the membrane is permanently attached to the diffuser body. The ECT unit is attached to a saddle that is mounted on a distributor pipe. The diffuser becomes a cartridge that you can replace, while leaving the saddle alone. Many operators prefer to replace a diffuser cartridge, rather than taking a diffuser apart and replacing diffuser components. The work goes faster, and there is less time spent in a confined space open to the elements. Click to learn about SSI's ECT series of tube diffusers.

Expert Support

Count on the team at SSI Aeration, Inc. for superior customer service. Personal design assistance is available, as well as free software on our Technology Portal. SSI has a fully staffed engineering department that can help clients design their projects. Whether a customer plans to start from the beginning or needs extra support during development, our team can provide expert advice. The SSI Technology Portal offers resources that help clients create the aeration systems they need. These tools empower them to make custom price estimates, drawings and more.

Affordable Pricing

Many SSI fine bubble tube diffuser models have an affordable price for initial use or retrofitting. Choose from a variety of materials and connectors with varying costs and levels of performance. SSI designs every diffuser with quality, reliability and efficiency as the focus. Whether they choose a product on the affordable or advanced end, clients will receive a diffuser that lasts.

Other Applications for Tube Diffusers

SSI tube diffusers provide high capacity at an economical cost. Tube diffusers can offer a lower capital cost than disc diffusers, because there is less header piping and supports, and installation is faster. Aside from retrievable systems and aeration tanks, tube diffusers are also popular choices for equalization basins, aerobic digesters and post aeration systems, as well as flue-gas desulfurization projects (FGD). SSI tube membranes are available with 1mm or 2mm slits. In deep tanks, aggressive wastewater, and where capital cost (CAPEX) is more important than operating cost (OPEX), larger slits may be beneficial.

Installation Services

If you are in the market for new fine or coarse bubble aeration equipment, but you want to write a single purchase order, in many cases, SSI can provide installation services at your site for our tube diffusers. We have multiple crews that work for us throughout the country, who have experience with our equipment and are licensed and insured in your region. We work very quickly because installing diffusers is what our crews do every day. We go above and beyond, including working over holiday weekends, in order to get your aeration tank back up and running in the shortest time possible. We improvise on-site when we are missing parts or we discover unknown problems, in order to avoid unnecessary delays and to reduce callbacks.

MBBR Upgrade

Don’t waste money on new concrete tanks, if you don’t have to. SSI is a leader in the design and supply of right-sized fixed film reactors using fine bubble diffusers, such as SSI tube diffusers. We can take your old conventional activated sludge system and convert it to IFAS or MBBR, to provide extra capacity and/or higher levels of treatment. For a greenfield plant, you can save money and land by constructing a smaller biological reactor when you use media. Industrially, MBBR’s are hard to beat, because they are easy to run (no sludge blanket to monitor in the clarifier since there is no return sludge). MBBR’s are also resistant to shock loads, and are economical to build. Based in North Carolina, SSI’s MBBR group is an excellent resource.

Buy Fine Bubble Tube Diffusers Today

SSI Aeration, Inc. has an experienced team operating across the globe to give clients the support they need. To learn more about the worldwide choice of fine bubble tube diffusers, fill out the form below, and one of our experts will contact you. Clients can also request a quote today to begin the purchasing process. A team member will assist in designing a system that suits the required wastewater aeration application. Customers who need general information may contact a sales representative or consult with an expert.

Contact Us

Advantages and Disadvantages of MBBR Wastewater Treatment

Table Of Contents WHAT IS MBBR WASTEWATER TREATMENT? HOW DOES MBBR WASTEWATER TREATMENT WORK? ADVANTAGES OF MBBR WASTEWATER TREATMENT DISADVANTAGES OF MBBR WASTEWATER TREATMENT INDUSTRIES THAT WOULD BENEFIT […]

EPDM vs. PTFE Membranes

Table Of Contents What Are EPDM Membranes? What Are PTFE Membranes? Choosing the Right Membranes for Your Application Contact SSI Aeration for World-Class EPDM and PTFE Membranes Many wastewater […]

A Comparison Of 5 Wastewater Aeration Systems & Processes

Table Of Contents WHAT IS ASP AERATION? HOW DOES ASP WORK? PROS AND CONS OF ASP WHAT IS SBR AERATION? HOW DOES SBR WORK? PROS AND CONS OF […]

Disc Diffusers vs. Tube Diffusers

Table Of Contents WHAT IS THE DIFFERENCE BETWEEN DISC DIFFUSERS AND TUBE DIFFUSERS? Pros of Disc Diffusers Cons of Disc Diffusers Pros of Tube Diffusers Cons of Tube Diffusers […]